- Home

- Cement Board

Cement Board Siding

Cement Board Siding for Older Homes; The Ultimate Solution for Worn-Out Wood Siding.

Cement Board (Fiber Cement) Siding for Homeowners: Why Cement Board Siding for your Home?

Cement board siding, also commonly referred to as fiber cement siding, has emerged as a highly sought-after exterior cladding solution for homeowners who demand both unmatched durability and enduring beauty. This innovative material blends robust performance with aesthetic versatility, positioning itself at the forefront of modern exterior renovation trends. In 2025, market data continues to highlight the rapid expansion and consumer trust in cement board siding, particularly in regions prone to harsh weather, wildfires, or pest infestation.

Cement board siding is more than just a passing trend—it is a long-term investment in your home’s protection, energy efficiency, and value. Whether you are considering siding for a new build or replacing aging exteriors, understanding the benefits, features, manufacturer offerings, and cost comparisons of cement board siding will empower you to make an informed, durable choice.

Concrete Board Siding. Resistant to rot, insects, high wind, and harsh weather.

Concrete Board Siding. Resistant to rot, insects, high wind, and harsh weather.Cement Board or Fiber Cement Siding can have an authentic-looking wood grain that mimics the look of real wood siding and shakes.

Cement Board Siding is a man-made composite material made form Portand Cement, sand, and natural fibers like cellulose. Also know as Fiber Cement Board, Cement Fiber Siding

Why Consider Cement Board Siding?

Why would you consider changing from wood siding to cement board siding?

There are several reasons:

Cement board siding or Fiber Cement Board Sidiing is actually stronger than real wood siding.

- Looks just like real wood siding, only stronger,

- Termite Resistant,

- Fire Resistant,

- Weather-resistant.

- More Durable Than Wood Siding,

- Is more budget friendly than wood siding.

- Aesthetic Versatility.

Concrete Board Siding is designed for harsh weather areas. Great for coastal areas where harsh winds, rain, strong sunlight, and even hurricanes.

Concrete Board Siding is designed for harsh weather areas. Great for coastal areas where harsh winds, rain, strong sunlight, and even hurricanes.Concrete Board is the Ultimate Solution

Concrete board is the ultimate solution for old worn-out wood siding. Homeowners with aging wood siding face a critical crossroads: how to rejuvenate their home's exterior with a solution that is both beautiful and long lasting.

As traditional wood siding weathers, it succumbs to pests, moisture and rot, and racks maintenance costs, more and more homeowners are seeking a superior replacement. Cement board siding (also known as fiberf cement siding or by leading brands like Hardie Board) is emerging as the smart, forward-looking choice for those seeking a robust, attractive, and cost-effective exterior that will stand the test of time.

Homeowners Seeking Lasting Value

Concrete board is for comeowners seeking lasting value, low-ongoing maintenance, classic and contemporary beauty, and peace of mind.

The Benefits of Cement Board Siding

Durability: Built to Last for Decades.

Cement board is renowned for its exceptional durabitity. Made from a composite of cement, sand, and cellulose fibers, this siding material is engineered to withstand the challenges that have historically plagued wood-siding.

Whereas wood siding is prone to rot, warping, splitting, and insect infestation biber cement remains steadfast. Numerouse reputable sources affirm that cement board siding can last for 30-50 years, often outliving the very roof above it.

- Five time thicker than vinyl siding,

- Significantly stronger than both wood and traditional engineered wood alternatives.

- Resistant to rot, termites, carpenter bees, and even woodpeckers.

- Able to endure winds up to 200 mph and stand up even to flying debris during powerful storms.

Concrete board is a superhero of home exteriors. It is tough, durable, and ready to withstand whatever Mother Nature throws hyour way. You won't even stress if a 50-mph wind gusts uour way.

Weather Resistant: No Fear of the Elements

Weather Resistance: Withstands extreme temperatures, heavy winds, hail, and moisture without cracking, swelling, or decay.

- Rain and Humidity: It won't absorb moisture, sweel, or foster mold and mildew-a critical advantage in rainy or coastal environments,

- Snow and Ice: Freeze-thaw cycles don't cause cement hoard to split or degrade, in stark contrast to wood which often crack or heaves,

- Sun and UV Exposure: Unlike vinyl or painted wood sidings, high-quality cement board siding is UV stable, resisting color fade and deterioration.

- Wind and Hail: Structural tests confirm fiber cement's surperior impact resistance, withstanding hail and flying debris that can ruin vinyl.

According to James Hardie’s rigorous field tests, fiber cement siding “offers superior water resistance,” resists swelling, cracking, warping, or splitting even after days of water immersion, and meets the country’s most stringent hurricane and flood zone codes.

Minimal Maintenance

Low Maintenance: Does not require frequent repainting or sealing; simple annual cleaning and periodic inspection.

Unlike wood, which demands frequent scraping, repainting, sealing, and pest control, cement board siding is celebrated for its low-maintenance lifestyle.

- A basic annual cleaning with a garden hose or gentle power wash is usually sufficient

- Caulking and touch-up painting may be required every 10–15 years, not every 2–5 as with wood13

- The finish lasts, especially with prefinished or ColorPlus™ technology coatings that resist chipping and peeling.

This translates to significant cost (and time) savings, freeing homeowners from endless cycles of DIY or expensive maintenance contractors.

Aesthetic Flexibility: Beauty for Every Taste

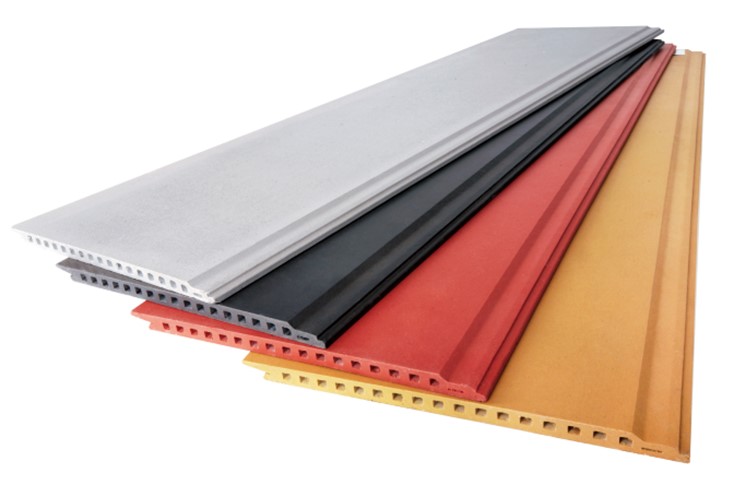

Aesthetic Versatility: Engineered to closely mimic wood, stone, stucco, or traditional lap boards with a variety of grain finishes and color options.

Cement board siding offers the versatility to create the exact look you desire, blending modern performance with classic curb appeal.

- Variety of Profiles: Lap, shingle, vertical panels, board-and-batten styles, and decorative shapes for accents17

- Authentic Wood Grain Textures: Achieve the natural, timeless beauty of wood without the headache 19

- Color Options: Factory-finished or custom paint in virtually any color, with the ability to repaint in the future for a fresh look

Whether your home is a Victorian, Colonial, Craftsman, bungalow, or mid-century modern, cement board has an option that can preserve originality and elevate curb appeal thus increasing value.

Design Versatiltiy

Classical and Contemporary Styles

Cement board siding appeals to a broad spectrum of tastes and home styles:

- Replicates wood, stucco, stone, and brick textures2

- Board and batten, vertical, lap, shingle, and custom patterns are available to maintain a historically accurate facade or create a modern, fresh look

- Hundreds of color options—factory or custom-painted; fade-resistant finishes keep colors vibrant

Modern fiber cement products can be found gracing everything from Victorian restorations to cutting-edge new builds. For older homes, this means you can maintain your classic wood aesthetic while eliminating ongoing headaches

Maintenance and Long-Term Savings

Maintenance and Long-Term Savings

- Painting: Needed every 10–15 years ($2,500–$6,000 per repaint for a typical house) versus wood’s every 4–7 years ($3,000–$7,000).

- Repairs: Much less frequent; patching with caulk or panel replacement is simple; little rot or pest remediation required.

- Annual upkeep: ~$200–$500/year for cement board versus $500–$1,000/year for wood siding (due to painting, pest work, rot repair).

Maintenance Requirements:

Preserve Your Investment Easily. Regular Care and Inspections

Cement board siding is not maintenance-free but is far easier to care for than wood.

- Cleaning: Once or twice a year with low-pressure water and mild soap; no scrubbing or heavy chemicals required13

- Caulking: Check joints and openings annually; re-apply as necessary (typically every 10–15 years)

- Painting: Factory-finished options offer 15–30 years of fade-resistant color; field-painted boards require repainting every 10–15 years

- Repairs: Small chips can be patched; damaged panels can be individually replaced without affecting the whole wall or finish.

Home Value and ROI

Home Value and ROI:

According to Remodeling’s annual Cost vs. Value Report, fiber cement siding replacement typically recoups 76–88% of its cost at resale—outperforming both vinyl (low 80% range) and wood (low 70% range)24.

Add in curb appeal, reduced insurance costs (fire/weather), and long-term savings, and cement board siding emerges as one of the best investments you can make in your property.

Long-Term Value

- Return on Investment: Fiber cement siding averages 76%-85% ROI on resale.

- Insurance Premiums: Possible annual homeowner insurance discount due to fire rating.

- Maintenance/Repair Savings: Less frequent repair and painting than wood.

Although the upfront investment for cement board siding is higher than vinyl, the long-term savings on maintenance, repairs, repainting, and insurance—as well as excellent ROI

Long-Term Value

- Return on Investment: Fiber cement siding averages 76%-85% ROI on resale.

- Insurance Premiums: Possible annual homeowner insurance discount due to fire rating.

- Maintenance/Repair Savings: Less frequent repair and painting than wood.

Although the upfront investment for cement board siding is higher than vinyl, the long-term savings on maintenance, repairs, repainting, and insurance—as well as excellent ROI—make it the most cost-effective option for many homeowners over the product’s life cycle.

Cost Analysis

Installed Price (Materials + Labor)

Upfront Investment:

Cement board siding costs more to install than basic vinyl or lower-end wood siding, but the initial investment is offset by its longevity, minimal maintenance requirements, and return at resale.

- Material cost: $1.50–$3.50/sq ft for materials; $4.50–$9.50/sq ft for installation21

- Installed cost: Typically $7–$14/sq ft, depending on home size, complexity, and region20

- Average 2,000 sq. ft. home: $14,000–$28,000 installed

While this is higher than “entry-level” vinyl ($3–$7/sq ft) and similar or less than high-quality wood (up to $16/sq ft, plus frequent repainting), cement board’s longevity and reduced life-cycle costs offer clear value.

It should be professionally installed by contractors.

DIY or Pro?

While ambitious homeowners can undertake fiber cement siding as a DIY project, professional installation is recommended for:

- Warranty compliance.

- Ensuring proper weatherproofing and expansion control.

- Reducing silica dust health risks.

Cement Board Siding. Strong and durable.

Cement Board Siding. Strong and durable.It resembles real wood siding but offers greater strength and durability. Many manufacturers offer a 50+ year limited transferable warranty due to its robustness.

This siding is resistant to rot, moisture, bugs, warp and harsh weather conditions such as high wind.

Concrete Board Siding. Shown here in rough-cut cedar texture.

Concrete Board Siding. Shown here in rough-cut cedar texture.It offers rich textures, from deep wood grains to smooth finishes, providing a realistic and rustic natural look.

Ideal for coastal areas due to its resistance to salt spray and UV rays. Withstands freeze-thaw cycles better than real wood.

House Siding Colors

House siding colors are an important aspect of any new siding. This type of siding can be painted with any good quality paint in any color.

This type of siding can come h factory primer, often with option for factory pre-painting with the ability to paint with a custom color.

Concrete Board Siding can be painted any color.

Concrete Board Siding can be painted any color.It is Non-combustible so it will not ignite. Impervious to termites and other wood boring insects.

Fiber Cement Siding Cost?

Concrete board siding will run in the range from $4 up to $10 +per sq foot. The price will depend on many different factors such as how much prep work the contractor will have to do on your existing house to get it ready.

- Repair or Replace water damaged wood, and trim.

- How many stories are there? It takes much more labor to install on the second and third floors.

- How many corners are there? Corners take a lot of special work to turn the corner.

- How many windows and doors? Windows take a lot of time to frame around each window and door.

- What time of the year is it? Contractors may be busy or sitting around waiting for jobs.

Product Comparisons: Why Cement Board Siding ExcelsA. Cement Board vs. Vinyl Siding

- Durability: Cement board outlasts vinyl (50+ years vs. 20–40 years).

- Fire Resistance: Vinyl can melt or ignite; cement board will not burn or support flame spread.

- Appearance: Fiber cement provides more realistic wood, stone, or custom textures and can be repainted; vinyl is limited in color and may fade.

- Impact Resistance: Cement board resists hail, debris, and wind better.

- Maintenance: Vinyl never needs repainting; cement board needs repainting every 10–15 years, but requires far fewer repairs.

For more information on How to Find The Cost of Siding Click Here